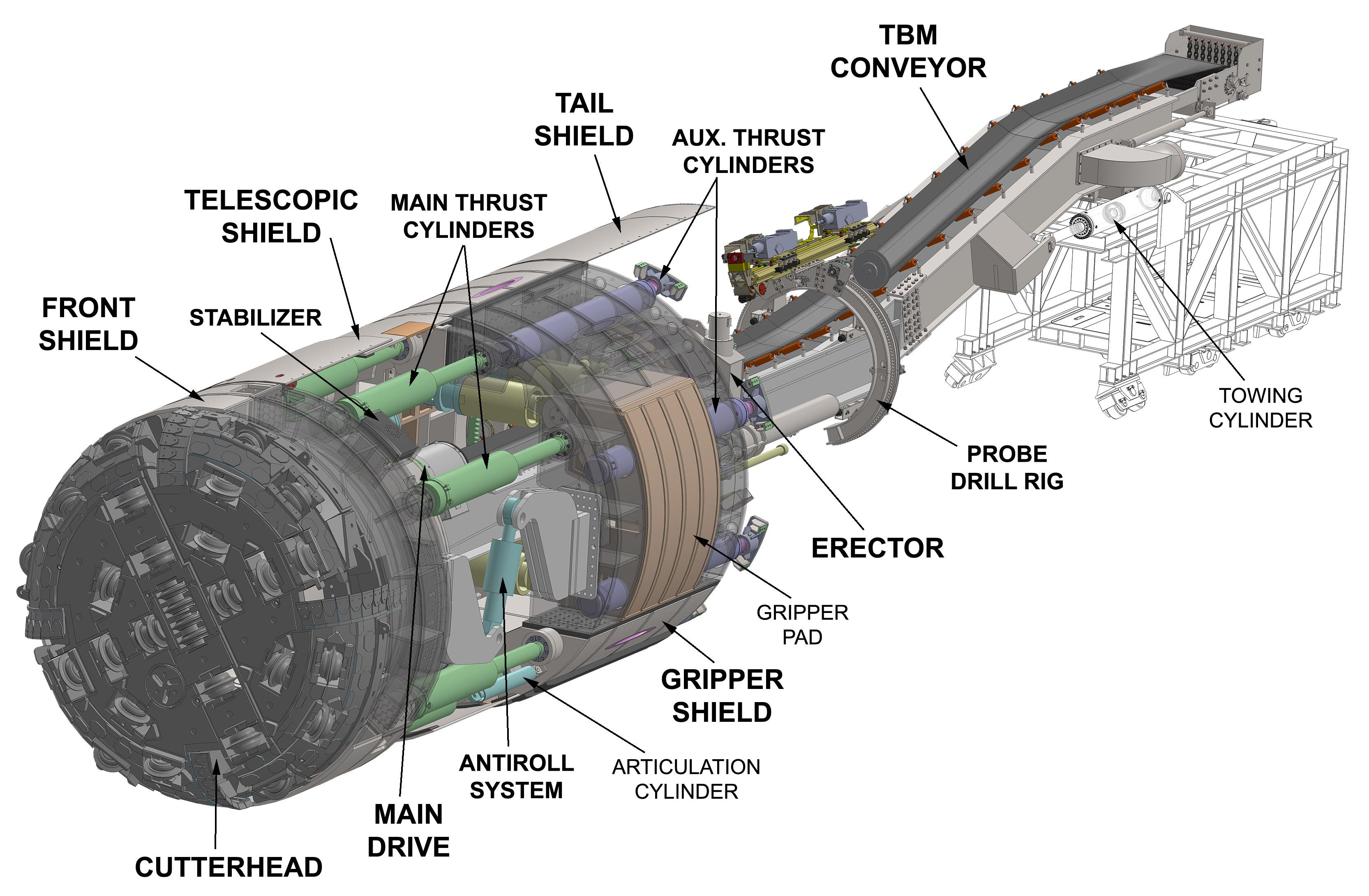

The Double Shield (DS) TBM concept was designed and patented in 1971 by SELI, TunnelPro's parent company, in cooperation with Robbins. This type of TBM has the shielded part divided in two main sectors, with the rear one that is gripped to the tunnel walls so that forward thrust can be exerted on the cutterhead without needing to push on the gallery lining. In standard mode the machine therefore advances with a telescopic motion which has the following advantages with respect to single-shield machines:

- Versatility: The machine can be used without needing to mount any tunnel lining. It can also be utilized as a single-shield machine using the auxiliary thrust cylinders;

- Safety: The TBM operating areas are completely shielded at all times;

- Performance: Boring and lining procedures can be carried out at the same time.

The video below shows a typical boring cycle of a double-shield TBM, in which excavation and lining operations are carried out at the same time.

The main characteristic of a DSU is a decreasing diameter of the shields from front to back that was proven to increase the general performances because of the following additional advantages:

- Avoids TBM blocking in squeezing grounds;

- Facilitates steering;

- Reduced total TBM length (similar to a single shield TBM of same diameter);

- Extends the DS application range beyond the typical 4÷7 m of excavation diameter.