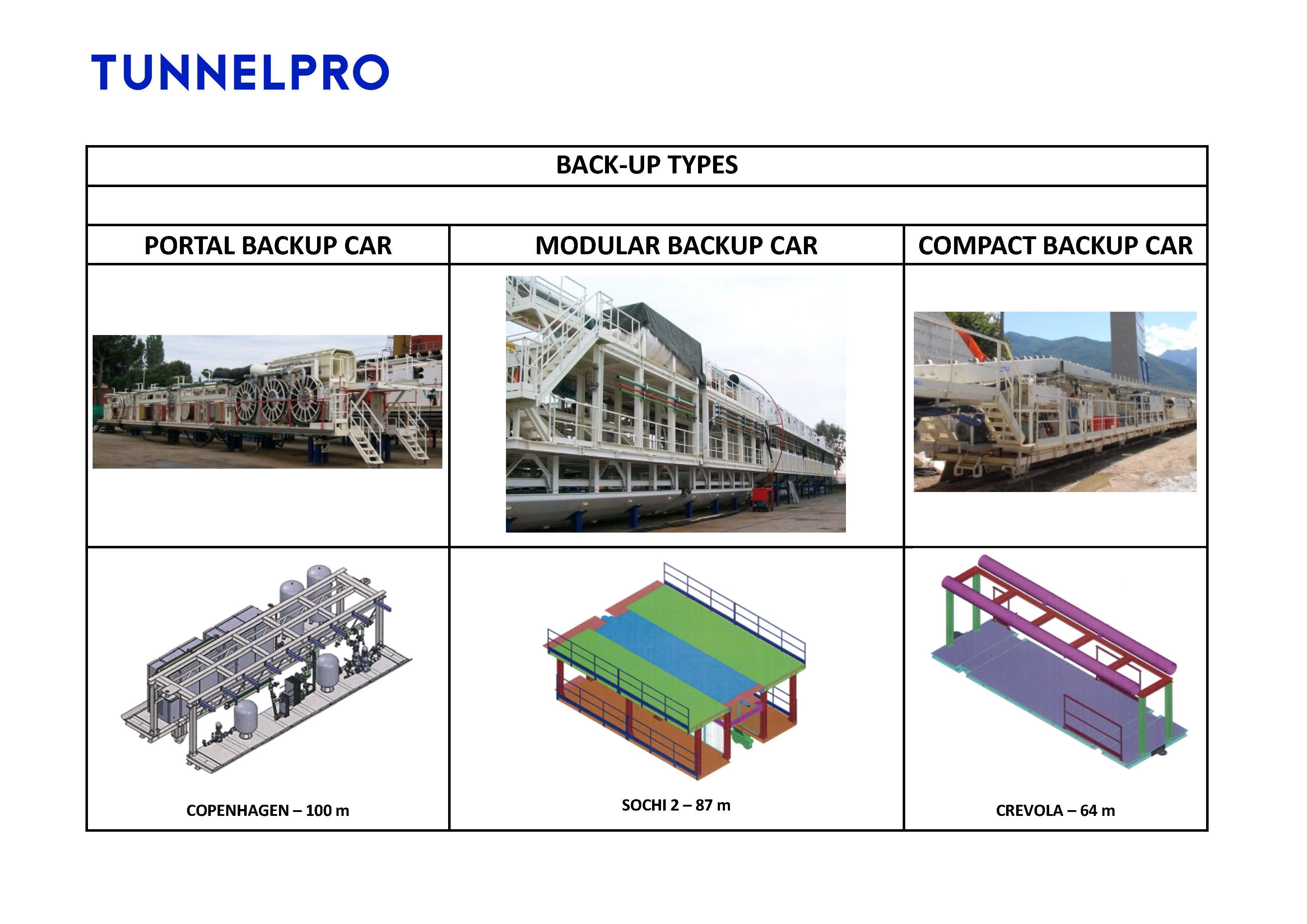

TunnelPro boasts decades of experience in designing and manufacturing back-up systems suitable for every type of TBM. Over time, we have developed several layout concepts—modular, compact, portal, and discrete—to meet a wide range of operational and logistical requirements.

The following solutions represent standard features of TunnelPro-designed back-up systems:

- All back-up cars are built with bolted components to simplify disassembly and transport operations.

- Each piece of equipment is mounted on an independent structural frame installed on the back-up car, allowing easier assembly and disassembly.

- All TBM auxiliary equipment (hydraulic units, electrical panels and operator consoles, transformers, lubrication units, and more) is installed on the cars closest to the TBM to facilitate connections, testing, and operation.

- All operations are fully mechanized, eliminating the need for manual operations.

These solutions provide several operational advantages, including:

- Increased safety in work areas

- Improved efficiency of the tunneling system

- Increased productivity of the tunneling system

- Reduced labor requirements for TBM management

- Lower costs and shorter times for assembly, disassembly, and transport

- Operational compatibility with both conveyor-belt mucking systems and solutions based on rolling stock or rubber-tired vehicles.